Industrial Metal Fabricators (IMF Conveying Systems) offers technology driven solutions to satisfy the pneumatic conveying requirements of today’s plastics industry.

Our company offers complete turnkey systems for pneumatically conveying:

- Virgin Pellet

- Regrind Products

- Powdered Products

- Plastic Trims

- Plastic Bottles

- Finished Bottles

- Finished Bottles/Products

Throughout our years of experience, we have installed hundreds of projects using Negative Pressure and/or Positive Pressure systems. We have also patented several devices including our F.V.O Venturi System, which provides a non-contact method of conveying various products.

Our engineering and technical staff specialize in pneumatic conveying and material transfer systems and at the same time, understand our customers’ processes and concerns. Our goal is to find the best possible solution for each customer.

If you are faced with a difficult conveying problem, we would greatly appreciate the opportunity to “Deliver the Solution.”

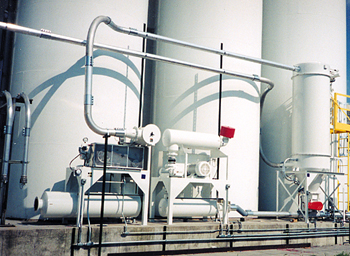

Negative Pressure Systems

Some key features include:Negative Pressure System

- Vacuum take-off box, Rotary Airlock or Butterfly Valve infeed

- Convey Line Piping Components available in:

Mild Steel

Aluminum

Stainless Steel

Flow Lined Piping - Abrasion resistant construction (optional)

Download Negative Pressure Flow Schematic

Positive Pressure Systems

A wide variety of option for system and component design are available depending on the particular requirements of each application.

Some key features include:

- Pressure Blower or Positive Displacement

- Convey Line Piping Components available in:

Mild Steel

Aluminum

Stainless Steel

Flow Lined Piping - Rotary Airlock or Venturi Style in feed

- Single or Multiple Pick-up and Discharge Points

Download Positive Pressure Flow Schematic

F.V.O Adjustable Inline Venturi System

Our patented Inline Venturi System is a non-contact mode of transferring carious products, some of which include:

- Plastics (EPP, EPS, EPE)

- Continuous Trim

- Molded Bottles

- Aluminum Cans

- Finished Products

- Waste Materials

By removing our air return unit, we are able to effectively exhaust corrosive, explosive or hot gases. Various sizes are available from 1-36 inch diameter.

By conveying EPS beads with the FVO as opposed to through a fan, we are able to reduce the bulk density of EPS from 1.20 to 0.93, a 29% increase in material output**.

C.E.S. Continuous Evacuation System

Our Industrial Duty Design Incorporates:

- Industrial Duty Cyclone

- Machined Rotary Airlock

- Industrial Duty Blower

- Support Structure

- Service Guide Rail System

- Support Structure

- Filter System

The negative pressure system requires minimal maintenance and as operator friendly.

Available options include:

- Stainless Steel Construction

- Abrasion Resistant Construction

- Gaylord Stand

- Metal Detection

- Filter System

- Perforated Basket

The C.E.S. can be used with the following materials:

- Regrind

- Pellets

- Finished Component

Photo shown in Service Position

**29% increase in output is based on BASF Michigan facility. Rate will vary slightly per job.